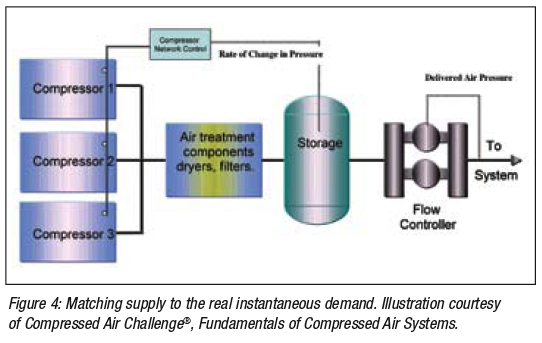

Understanding the components of both sides will help you identify improvements and inefficiencies in the process and match the supply and demand levels.

Compressed air system design calculations.

Example 10 size pipes for compressed air system.

P2 125 14 7 139 7 p1 85 14 7 99 7 c2 448 39 total cfm requiredwe need an additional 128 39 cfm to raise system pressure to the.

Compressed air system design calculations.

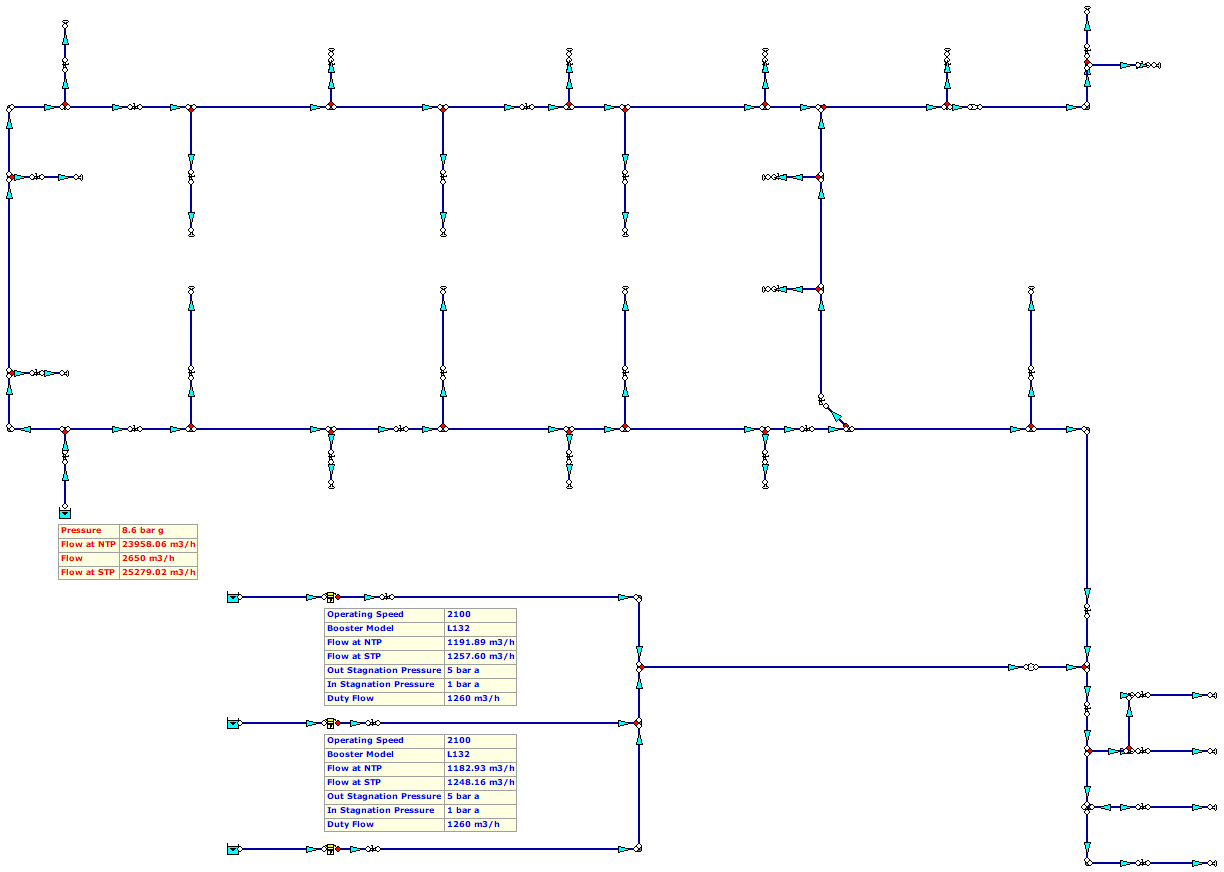

The compressed air pipe routing design and dimensions are important factors for the efficiency reliability and cost of compressed air production.

To deliver compressed air to where it is needed.

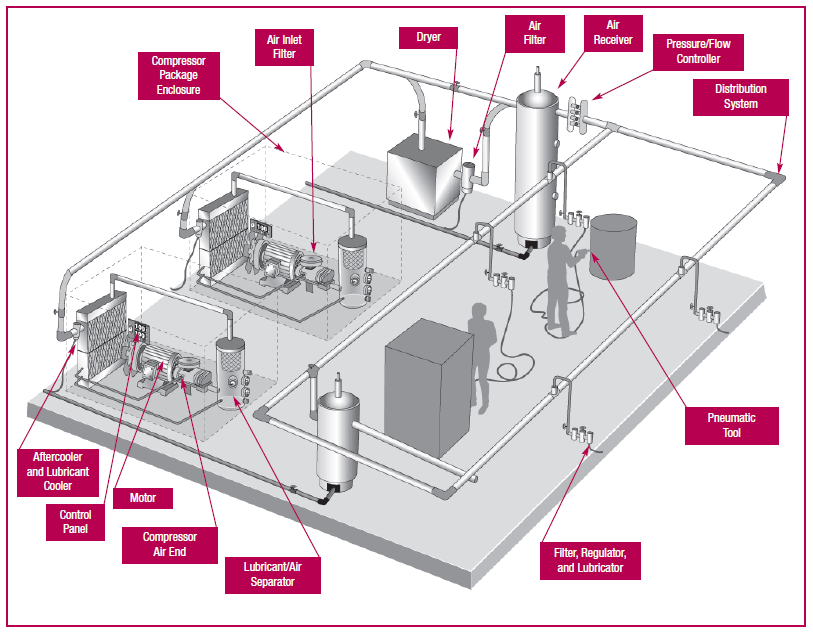

1 system overview 2 compressed air ratings 3 types of compressors 4 system design considerations 5 compressor controls 6 compressor sizing 7 system configuration 8 air quality 9 components of compressed air system 10 compressed air treatment 11 after coolers 12 dryers 13 compressed air filters 14 six levels of compressed air treatment quality.

Use our compressed air system design calculator for free it only takes a few seconds to complete the form and might save you a lot more time and money.

However designing a compressed air system is more difficult than you might imagine the compressed air has to be delivered with sufficient volume good enough quality and enough pressure to power the components that require compressed air.

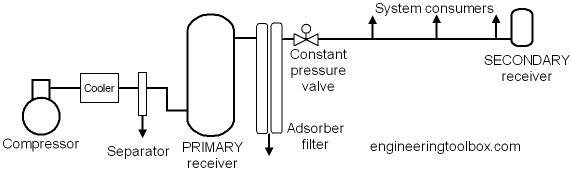

Let s look at the supply side first.

Moreover the decades of knowledge and expertise from this industry leading system provider are made available to each and every customer via the kaeser group s global computer network.

Influence of bends couplings and other stuff to pressure drop.

Design your own compressed air piping system.

Our drag and drop features give you complete control over your design.

Rapidair s system designer is a free 3d drawing tool that will help you easily create a compressed air piping system for your facility or workshop.

The purpose of compressed air piping systems is simple.

Compressed air supply and demand refer to the two sides of a compressed air system and influence many different aspects of its efficiency.

Boundaries of performance and compressed air effi ciency.

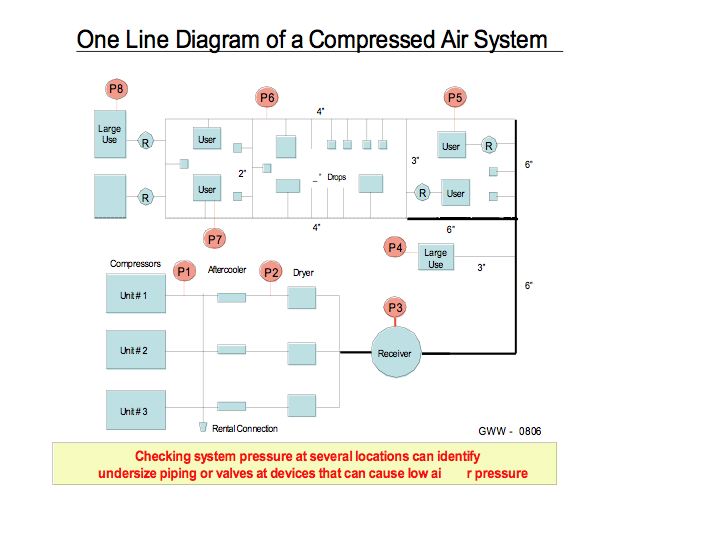

Compressed air system piping design this example shows a compressed air system where the air is distributed around a ring main loop system to maximize distribution efficiency when some demands are not in use.

Learn what you need to keep your systems running efficiently with our easy to use air compressor calculations and formulas tool.

When you ve completed the design save your project by creating an account.

Compressed air pipe sizing table in millimeters.