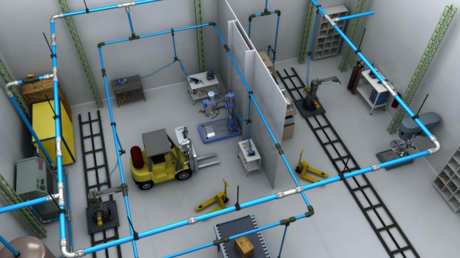

Typical components include a water source a centrifugal pump foam concentrate tanks a direct injection foam proportioning system on the discharge side of the pump a mixing chamber or device a rotary air compressor and control systems to ensure the correct mixes of concentrate water and air.

Compressed air foam system advantages.

Compressed air foam clings well to vertical fire exposures which means less water is wasted from runoff during exposure protection operations.

However we are now finding ourselves facing an in depth strategic review concerning our approach to structural firefighting where it has been shown that fire attack systems providing foam air additives can assist firefighters greatly.

A compressed air foam system is used in firefighting to deliver fire retardant foam for the purpose of extinguishing a fire or protecting unburned areas.

The use of compressed air foam systems cafs in the rural setting undoubtedly offer great benefits as do regular class a foams for their penetrating and protective qualities.

Second the high energy of a caf stream provides a longer reach allowing firefighters to operate farther away from the incident in a safer location.

In rural areas where water supplies are scarce if exposure protection applications are needed more water remains available for offensive fire attack.

Cafs uses a class a foam concentrate combined with water and compressed air to form a fire extinguishing agent that is greater than the sum of its parts.

Some of the benefits of foam include.

Foam maintains a longer wet contact time than a fluid.

The synergistic effect is a product with.

Benefits of foam foam is quickly becoming the tool of choice for first responders around the world.