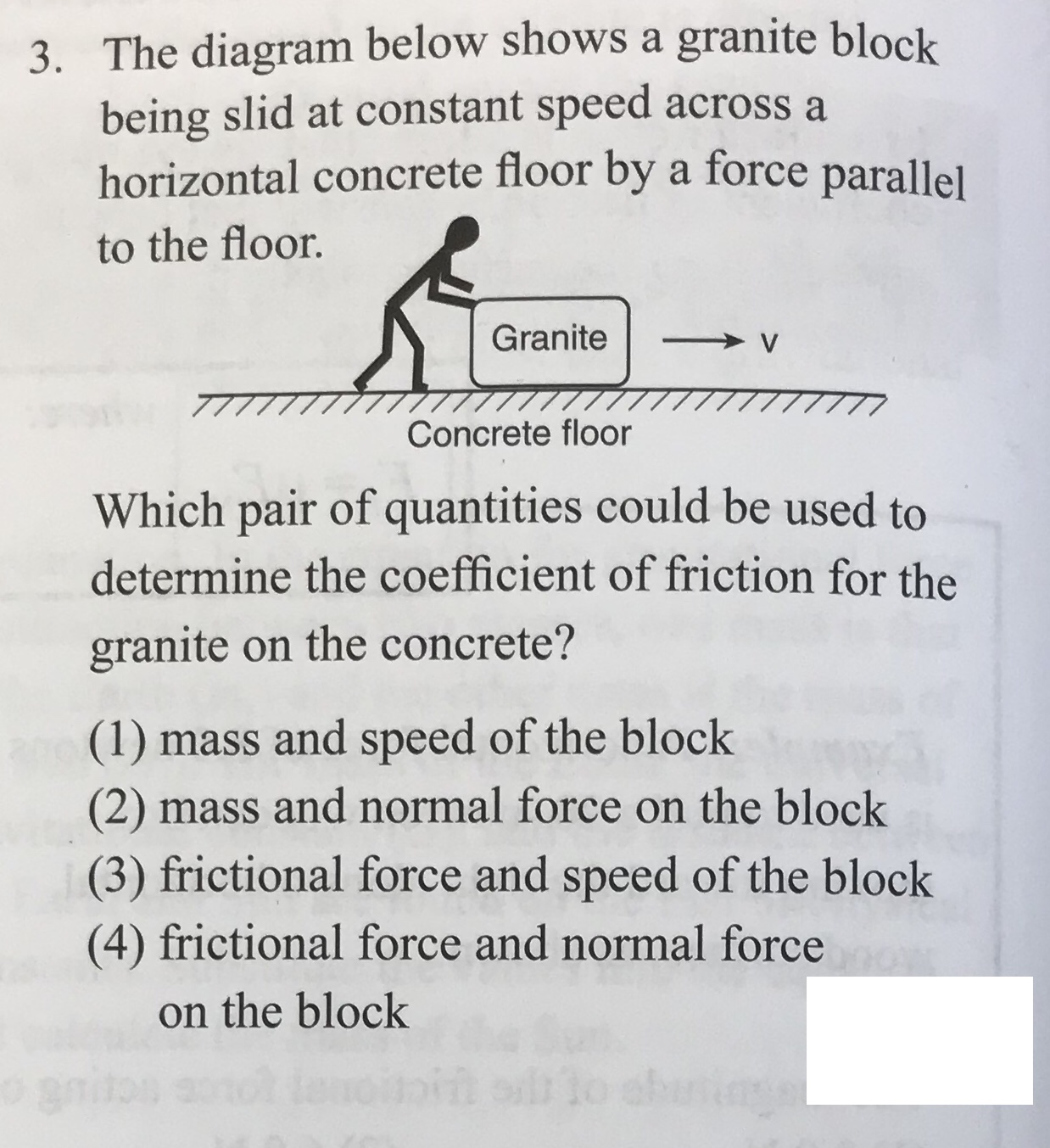

The coefficient of static friction typically denoted as μ s is usually higher than the coefficient of kinetic friction.

Coefficient of friction of aluminum with granite.

The coefficient of friction is required in calculating tightening torques and resulting bolt tensile forces and stress and in calculating the resulting friction between the connected surfaces.

Static friction is friction between two or more solid objects that are not moving relative to each other.

For example static friction can prevent an object from sliding down a sloped surface.

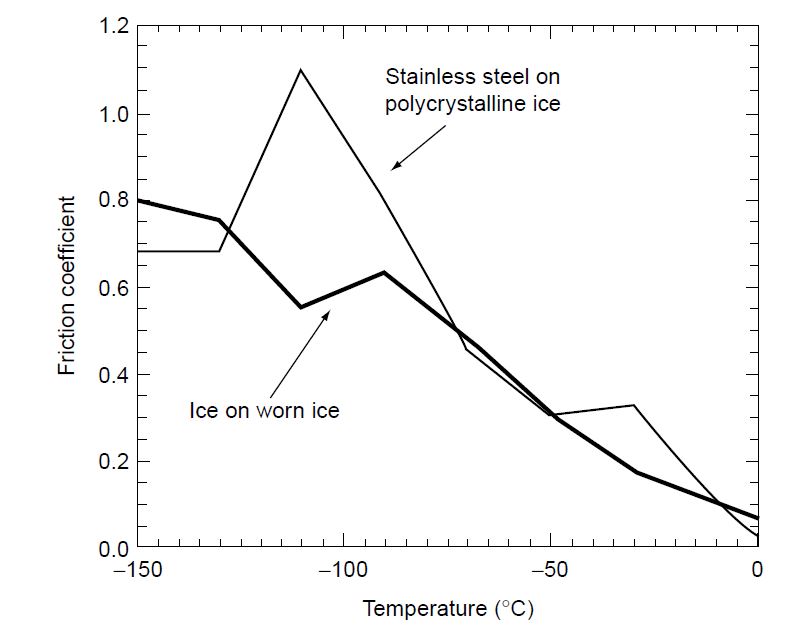

From different studies it is revealed that various field process wear parameters influencing wear coefficient of friction of amc s.

F f μ n 1.

F f frictional force n lb.

N normal force between the surfaces n lb there are at least two types of friction forces.

The frictional force can be expressed as.

Below are provided a small number of values showing approximate values of friction coefficients to be used for steel screw fastened connections.

The friction force is the force exerted by a surface when an object moves across it or makes an effort to move across it.

Coefficient of friction to 0 25 to 0 3.

Ref links 1 below the american gear manufactures association agma recommends a value of between 0 12 0 15 for hydraulically expanded hubs and 0 15 0 20 for shrink or press fit hubs.

μ static μ s or kinetic μ k frictional coefficient.

First you tape the low g accelerometer on the end of the surface in this case a slab of granite.

The coefficients of friction are independent of the surface area in contact.